Applying Industry 4.0 in companies

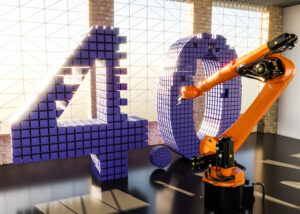

First, we will start by developing the concept of Industry 4.0, also known as the fourth industrial revolution, which refers to the integration of advanced digital technologies in industrial production and manufacturing processes. This revolution is characterized by the interconnection of physical systems with cybernetic systems, enabling real-time communication and data exchange between machines, systems and people.

The application of Industry 4.0 in a company, for example, industrial equipment, can provide numerous benefits in terms of efficiency, productivity and competitiveness. Here are some key areas where it could be applied:

- Internet of Things (IoT): Regarding the connectivity of devices through the Internet, it allows the collection of real-time data from industrial equipment and machines. This can help monitor performance, identify problems early and perform predictive maintenance.

- Automation and robotics: The automation of industrial processes and the introduction of robots can increase the efficiency and precision of operations. Robots can perform repetitive, dangerous or high-precision tasks, while employees can focus on more strategic activities.

- Augmented reality and virtual reality: These technologies can be used for employee training, process simulation or design visualization. Workers can receive real-time instructions through augmented reality devices and perform complex tasks more efficiently.

- Systems integration: Integrating systems throughout the entire supply chain, from material procurement to final product delivery, can improve visibility and efficiency across the enterprise.

- Cybersecurity: With increased connectivity, it is critical to secure systems and data against potential cyber attacks. Implementing robust security measures is essential to protect industrial infrastructure and sensitive data.

That is why Industry 4.0 seeks to transform traditional manufacturing systems into smart factories, where equipment, machines and processes are connected and are able to make autonomous decisions and adapt to market demands in an agile way. In addition, it is important to keep in mind that the implementation of Industry 4.0 will require investment in technology, infrastructure and personnel training. However, the long-term benefits in terms of efficiency and competitiveness can far outweigh these initial costs.

To contact our specialists, please write to us at the following link: wa.link/cb2zxe

Marketing